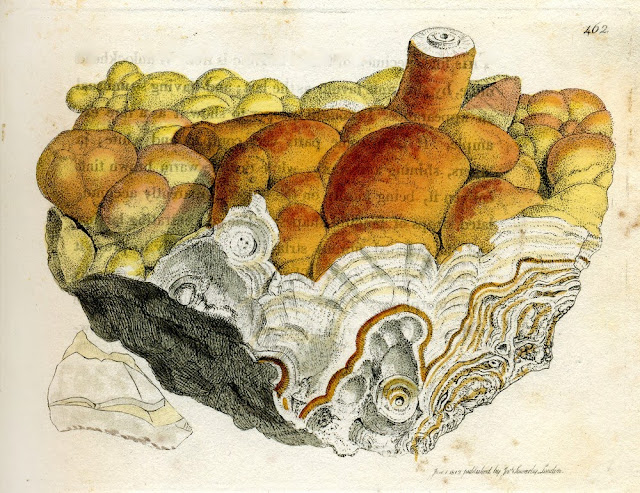

Crushed samples of feldspar from Scotland

Potash feldspar was first in demand for the production of fertilizers, later during the Second World War deposits of potash feldspar were investigated for the production of ceramic ware. British Geological Survey Petrology Collection sample number MC 7436. To extract the potash numerous methods have been devised. They include 1. Simple wet grinding and electrolysis, this proved unsuccessful and only one-third of the alkali present could be extracted by this method. 2. Treatment with chemical solutions, either caustic alkalis or acids. 3. Volatization of potash-salts, this involved heating feldspar with gypsum and carbon with potassium sulphate being volatilized and then recovered. 4. A number of dry processes for the separation of potash existed e.g. separation of potash as hydroxide or carbonate; as sodium or potassium chlorides; extraction of sodium and potassium sulphate.

Bob McIntosh